Print Large Format Graphics

With Full Confidence

Strike-Off Proofs on Up To 3 Different Materials

The Power of Proofs: Seeing & Feeling is Believing

Before ordering a finished product, we believe you should hold your design in your hands, on your chosen material, under your actual lighting. This is the best guarantee that your vision translates from theory to reality.

- ✅ 95% of our projects use proofs

- ✅ 1200 DPI production-quality samples

- ✅ 40+ substrates available to test

- ✅ 5-7 day standard turnaround

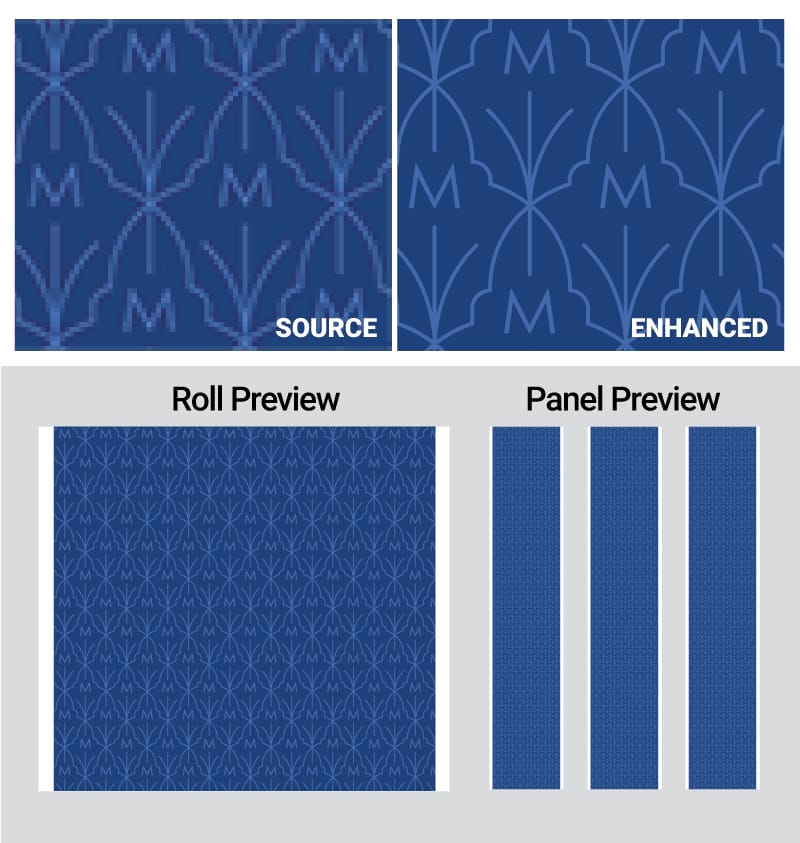

Step 1: Prepress Review & Artwork Processing

Before printing your proofs, our co-founder Steven reviews your files for technical precision. This isn't generic QC. Steven catches scale miscalculations, pattern breaks that create awkward alignments. He also enhances artwork to eliminate resolution issues that would compromise print quality.

Digital Layout Schematics & Previews

You will also receive a technical panel map showing how your design breaks across 52" wide panels and maps to your wall dimensions. This catches layout problems before they become expensive reprinting disasters.

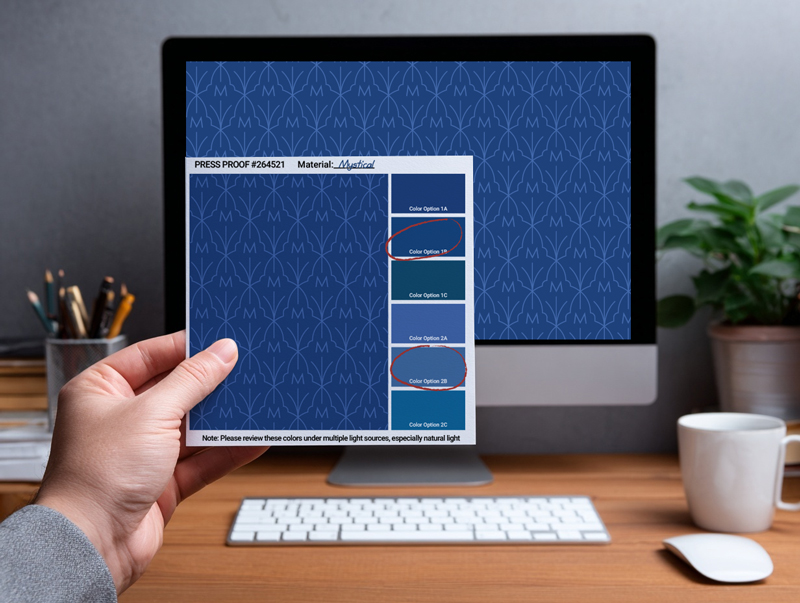

Color Matching Precision for Branding & Replication

We maintain a 20,000+ color library achieving Delta-E <1 accuracy for matching specific color codes from established brands like Pantone, Benjamin Moore, Behr, Sherwin Williams + more.

Step 2: Material Consultation

Select 1-3 substrates to test from our 40+ material library. Most clients compare:

- Type II commercial vinyl vs. non-woven (durability vs. texture)

- Traditional Unpasted vs. peel-and stick substrates

- Matte vs. textured finishes (modern vs. organic)

- Standard vs. specialty materials (canvas, grasscloth, metallic)

Our founders recommend materials based on two criteria:

- Desired Visual/Tactile Effect: Whether you favor a paper, plaster, or textile finish we have you covered.

- Environmental Specifications: hospitality corridors require different specs than corporate offices or residential feature walls.

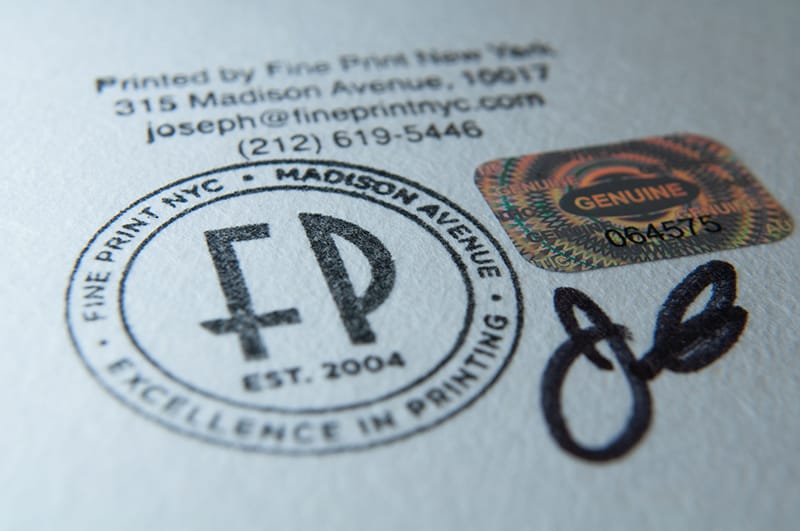

Step 3: Physical Proof Production & Approval

We print production-quality samples (18"x24" standard size) on your chosen materials at full 1200 DPI resolution. These aren't mockups—they're printed on the exact substrates with the exact UV-cured inks your final rolls will use.

What You'll Evaluate

- ✅ Color accuracy under your actual lighting conditions

- ✅ How texture affects the look and feel of your design

- ✅ Printing quality and fine detail of high-definition resolution

- ✅ Material durability, finish, and commercial-grade performance

Approval Protocol

Once you sign off on a proof, it becomes your production standard. We keep it on file for batch consistency and future reorders. What you approve is exactly what ships.

Why We Recommend Proofs for Every Project

While printing a sample does increase lead time, there is no question that the return on investment is 100% worth it. Live press samples eliminate a lot of guesswork, headaches and wasted time when you actually see and feel what it is you are paying for.

All too often something looks great on a screen, and then either the quality or colors of the print don't match expectations. Proofs exist to catch errors ahead of time with small, affordable prints which can either be approved for production or modified to match expectations.

Accurate Color Matching

Problem: Your design's blues look perfect on a monitor. But printed on vinyl under 4000K office lighting, they shift purple. Under natural daylight in the lobby, they read turquoise. This is known as metamerism — colors that match under one light source but fail under others.

Solution: You review samples under YOUR actual lighting. If there's shift, we adjust ink values before production. This is why we photograph proofs under multiple light sources and why Joseph personally reviews every color-critical project.

Proper Texture Assignment

Problem: Your intricate pattern looks stunning on smooth matte. But your facility requires Type II scrubbable vinyl for code compliance — and that embossed texture obscures fine details you didn't anticipate.

Solution: You see how your design performs on each substrate before committing. We often recommend simplifying patterns or switching materials based on what physical samples reveal. Textured substrates can add richness to large-scale designs but destroy fine typography.

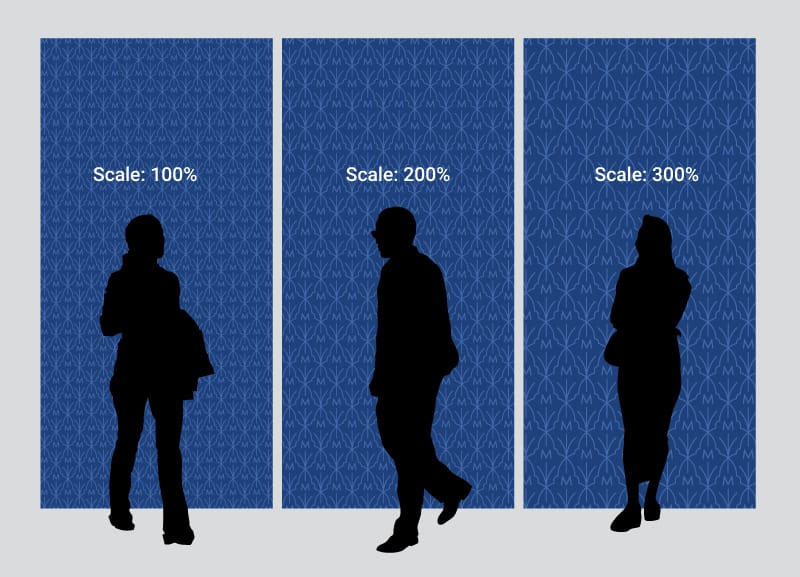

Scale & Layout Adjustments

Problem: Your repeating pattern has a 36" vertical repeat. Your wall is 9.5 feet tall. That means the pattern breaks awkwardly at the ceiling, cutting off key design elements or creating visual tension.

Solution: Steven's prepress review includes panel layout schematics showing exactly where breaks occur. We can adjust scale, shift alignment, or suggest design modifications before printing. This is the value of 40 years of pattern expertise.

When Do Clients Skip Proofs?

Extreme Time Constraints

Rush installations where 5-7 days matters (trade show graphics, event deadlines). We require very simple designs on materials we've printed extensively. Even then, we strongly recommend proofing.

Exact Repeat Orders

Client is reordering the exact same design on the exact same material from a previous job. We use the original approved proof as the production standard and batch reference.

Simple, Low-Risk Designs

Solid color backgrounds, basic text layouts, no critical color matching required. These represent <2% of our projects, and we still recommend proofs for large commercial runs.

When Clients Skip Proofs, They Accept:

- ⛔️ No recourse for color dissatisfaction (what prints is final)

- ⛔️ Full responsibility for design-substrate mismatches

- ⛔️ No adjustment opportunity before full production commitment

- ⛔️ Standard production timelines with no accommodation for reprints

Proof Pricing & Timeline

Popular Materials & Substrates

All of Our Substrates are Code & Safety Compliant. View Certifications | Browse all 40+ Materials

Frequently Asked Questions

How long are my proofs valid for approval?

Proofs remain valid for 90 days from delivery, giving you ample time for stakeholder reviews and lighting tests.

After 90 days, we may need to reprint if substrate formulations or ink batches have changed, ensuring your production matches exactly what you approved.

Can I keep the physical proof samples after approval?

Yes, the physical proofs are yours to keep for reference, client presentations, or installation coordination.

We maintain digital records and a physical archive of your approved proof for production consistency and future reorders.

What file formats do you need to create accurate proofs?

We accept TIFF, PSD, AI, EPS, and PDF files at 150 DPI minimum (300 DPI recommended for best results).

Our prepress team will review your files during Step 1 and flag any resolution or color mode issues before printing proofs.

Do I still need proofs for exact repeat orders?

No physical proofs required for exact repeats—we use your original approved proof as the production standard.

However, if you're changing substrates or adjusting colors, new proofs are essential to verify how those changes affect your design.

Can you match colors from a photograph or fabric swatch?

Yes. Joseph uses our spectrophotometer to analyze physical samples (fabric, paint chips, printed materials) for precise color matching.

Photos are less reliable due to lighting variables, but we can use them as starting references and then refine through proof iterations.

What if I need proofs larger than 18×24 inches?

Custom sizes are available, priced by square footage beyond the standard 18×24 sample.

Larger proofs are helpful for evaluating pattern scale on big installations—contact us for sizing recommendations and pricing.

Will the proof show the exact texture of my chosen substrate?

Yes. Proofs are printed on your actual production substrate using the same 1200 DPI process and UV-cured inks.

What you feel and see on the proof is exactly what your final rolls will deliver—texture, finish, durability, and all.

Nolar

Nolar Artist Canvas

Artist Canvas Mystical

Mystical Classic

Classic Mastering Proofs to Recreate Wallpaper

Mastering Proofs to Recreate Wallpaper Buyer's Guide for Types 1, 2, Peel & Stick Wallpaper

Buyer's Guide for Types 1, 2, Peel & Stick Wallpaper